|

Find Out Your Ring Size

Use this Ring Size Chart to size your finger for the ring. Save a copy of the PNG to your computer.

Print out the chart 200ppi from Photoshop

Cut out the Ring Size template, measure your finger.

Select the Modeling section of Maya, choose from upper left, status line.

Add the chart to an image plane to match the size

Select Create->Free Image Plane

Use the Attribute Editor (Ctrl a)

Select Image Name folder, add the ring size chart

Bring down the Color Gain a bit darker

Re-select the image plane

Use the Channel Box (Ctrl a)

Hit the arrow up button to see the transformation options, or reselect the image plane.

Choose the image plane, Rotate X -90 degrees

Choose the image plane, Scale X, Y, Z 1.27, 1.27, 1.27

(In Maya each grid unit = 1 cm)

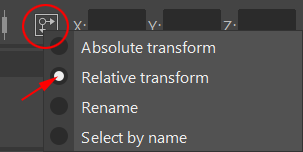

Input, Relative Transformations

Switch the selection button to Relative transformation in the Input Type box, on the status line, on the top middle right side of the screen. (Sometimes this is hidden if your screen is small, click on the show/hide buttons to expand hidden sections.)

When you enter a value in the box for a transformation, such as scale, rotate, or move, the object or component will transform will move relative to its position.

Make Some Guide Shapes

Diameter and size Curve

Create->Curve Tools->CV Curve Tool->

Select Curve degree: 1 Linear

Use grid snap x and click the first point in the top view at the origin, 0,0,0

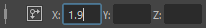

Input the second point in the Relative Transform box X: check your ring size, mine is a size 9 so I will input 1.9 cm.

Use Display->NURBS->CVs to show the CVs

Use the curve as a diameter guide.

Minimum print dimensions

Make a .1 cm guide, Shapeways does not let you print metal objects thinner than .1 cm.

Make a .2 cm guide, the height of the ring will need to be .2 cm or more.

Circle

Select Create->NURBS Primitives->Circle->

Normal axis: Y

Radius input half your ring diameter size (my ring size 9: 1.9 cm / 2 = .95 cm)

Number of sections 80

The circle should match the ring size on the chart in the image plane.

Circumference

If you need to know the circumference use, perhaps make a guide for this too.

Pi * diameter (for my size 9: 3.14159 * 1.9 cm = 5.969021

Use any tools to model a ring.

Inspect your model for holes or flipped faces.

Use Mesh->Fill Hole to fill holes

Use Edit Mesh->Merge to clean up your mesh, careful the tolerance does not delete the wrong points.

Bend a Flat object into a Ring

If you start with a flat shape, such as a cube

Use Create->Polygon Primitives->Cube->

Width: .2

Height: .1

Depth: 5.9690 Pi * diameter (for my size 9: 3.14159 * 1.9 cm = 5.969021)

Depth divisions: 80

Axis: Y

Rotate the cube 90 degrees around Y

Select Modify->Freeze transformations

Delete the 2 end faces

Select the Cube

Use Deform->Nonlinear->Bend

Rotate the bend deformer to match the intended bend, 90 degrees around Z

Use the Channel Editor to modify the Curvature of the Bend (180 degrees)

Use Edit Delete by Type->History to delete the Bend deformation

Rotate the ring 90 degrees around X and match it to the diagram. You will need to scale the ring up a bit.

Use Edit Mesh->Merge to remove doubled vertices and seal holes.

Embossing and Engraving

The minimum embossing or engraving is .03 cm wide and high, better to use .04 cm

You may always taper the shape so the form does not form a 90 degree edge.

If your ring is embossed you may want to add a slight bevel to the bottom face of the boolean.

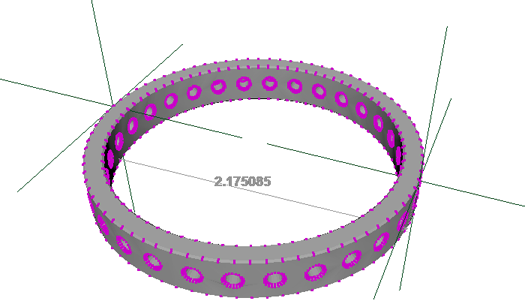

Check the outer diameter of you ring so you can compare it to the Shapeways scale

Select your ring.

Choose Display->Polygon->Vertices

Use Create->Measure Tools->Distance Tool

Use v point snap and shift to constrain to measure from the outer edge of the ring

Prepare your model

Edit->Duplicate, hide original

Edit Mesh->Merge input a very small number, .00001

Mesh->Cleanup-> select Lamina Faces select Lamina Faces

Select all the parts, use Mesh->Combine to make one object

Export your model

File->Save Scene As your scene as a backup, the software can crash exporting.

Select your model.

Choose File->Export Selection...

File type: DAE_FBX export .dae extension

Name your file Your name_Xsize_mm_material_ring_size.dae

The outer X dimension will be between 20-30mm, 2-3cm

Place this file in the drop/assignment_2_ring_models_DAE_FBX_OBJ folder on the class server

file.dma.ucla.edu port 22 /data/classes/Fall22/156/drop

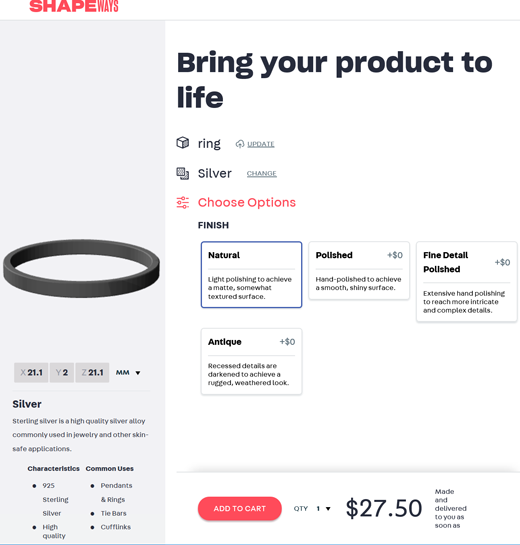

Uploading to Shapeways to test

The class has a minigrant, you do not need to pay. You will upload your model to the drop folder and I will print your model. This next procedure is a test to make sure it all works.

Go to www.shapeways.com and select upload

Make an account, make sure you apply for the 15% student discount for future prints.

Select the Smiley Face menu, choose Upload your DAE file or OBJ, choose your material.

If the MM size does not match your measured size, select RESIZE

Shapeways offers a preview where you should inspect your model again.

Check the scale and look for missing/flipped faces.

You are ready to print!

|